PART 1: BACKING

- The majority of ROLLINGDOG sandpaper is made with akraft paper backing.Some of the paper is latex coated tomake it better for wet sanding.This style of sandpaper willnormally be used with a hand sander,or wrapped around ablock of wood to for better use.

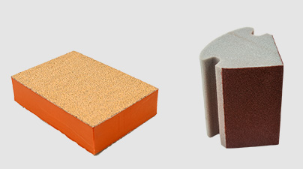

- Sanding sponges are a popular choice for small handsanding tasks as they make it easy to hold and controlwith a comfortable grip.

- ROLLINGDOG sanding sponges can berectangular or angled to sand effectivelyinto corners.

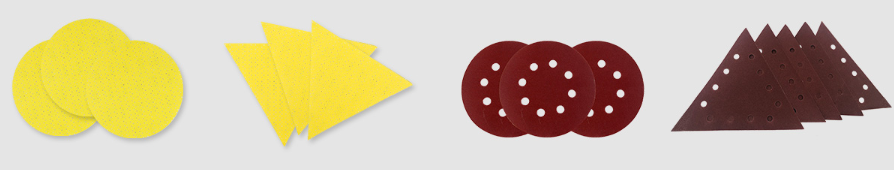

- Toimprove sanding while reducing fatigue ROLLINGDOG offers a variety PU foam handsanders with hook and loop attachment to sandpaper refills.This is a great option forsomeone who knows they will have work requiring sanding more than just once or twice.

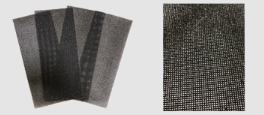

One of the latest sanding products added to the ROLLINGDOG lineup is mesh fabric sanding sheets,with thegrit attached to a poly mesh threads woven together for lessclogging and better contouring to surface shapes.

Other sandpaper used with power sanders also comes with holes around the paper fortools with vacuum attachment to reduce dust,clogging and buildup of material,effectively making it perform better.

PART 2: GRIT

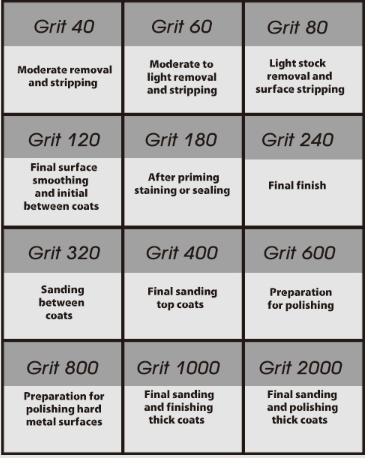

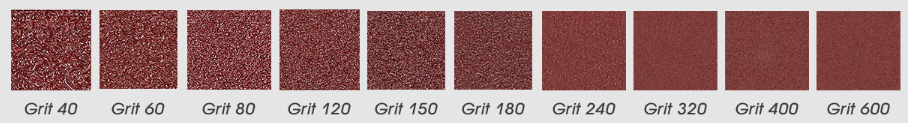

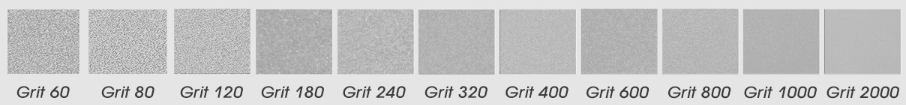

Sandpaper grit is referring to the smallcutting pieces attached to the backing material with an adhesive.ROLLINGDOG gritranges from 40 to 2000,with 40 being used forheavy surface removal and 2000 being for finemetal finishing.

There are several types of materials that grit is made from,with aluminum oxide and Siliconcarbide being the most common.The majorityof ROLLINGDOG’s sandpaper is made withAluminum oxide as it is more durable and longer lasting.But for finishing,silicon carbidewould be the preferred choice.Although it ismore brittle and less durable than aluminumoxide,its sharper and harder grains allow it toproduce a much smoother finish with high gritlevel sandpaper.

The majority of house painting and related projects will only need to be concerned with60 to 240 grit.Starting from the lowest grit you will progress up to higher grit in steps toensure no more than needed of surface is removed.Start with 60 grit if there are deepscratches or dents in the surface and once everything is level or looks similar you canbegin to smooth it out by using 80 grit,then 120 grit,then 180 grit,and finishing with 240grit for most wooden surfaces.Higher grits are needed for smoothing hard surfaces likemetal or fine surface scratches from hardwoods.

ALUMINUM OXIDE GRIT

- Block shaped grains works well on most materials

- Good starting point for metal and wood application

- Lasts longer than silicon carbide

SILICON CARBIDE GRIT

- Sharp needle-like grains allow fast removal

- Best choice for glass,plastic,rubber,and finishing stages of metal surfaces

- Is more brittle and breaks down faster than aluminum oxide

ASK ONE OF OUR REPRESENTATIVES ABOUT VIEWING OURFULL CATALOGUE TO SEE MORE OF WHAT ROLLINGDOG TOOLS HAS TO OFFER FOR SANDING PRODUCTS.

(CLICK THE DOWNLOAD PAGE TO DOWNLOAD THE CATALOG)